What is Lean Methodology? A Beginner’s Guide

Author

Auguste Usonyte

Published

If you couldn’t tell from our name, Lean Methodology sets the foundation of how we work at LeanConvert. This system allows us to deliver more value to the customers by building healthier, more productive, and more effective teams in which each person’s talents are used to their fullest potential. Essentially, this is done by focusing on the creation of value, continuously improving, and respecting people.

What are the Origins of Lean?

In the 1930s, Toyota (as in the Japanese car company) was having issues with its product delivery. They wanted to be the best car manufacturer in the world, but their manufacturing chains were too long, and they could not deliver the necessary amounts of production in time. Thus, they needed to develop a new product management system.

As a result, a man named Taiichi Ohno invented the Toyota Production System. This fresh approach aimed at reducing the cost of production, enhancing the quality of products, and increasing the throughput times so that dynamic customer needs could be better met.

This original version of Lean Methodology later revolutionised the manufacturing process in the 1950s and ‘60s. Any action that didn’t impact the functionality of the final product was considered waste. While Lean continues to be widely used in manufacturing, it has also fairly recently found new applications in software development and project management areas.

What are the Five Principles of Lean Methodology?

Defining Value

We can’t deliver value without knowing what is valuable for the client, right? When entering into a new relationship with a company, it’s crucial to start by understanding what they actually want to achieve, and then aligning the optimisation program accordingly.

Value Stream Mapping

Once you understand what value means to your client, the next step is visualising a path to the customer. This is basically a map of how value gets delivered to the client. Value streaming exercises are used to identify stakeholders, agree on roadmaps, define timelines and working agreements, etc. in order to consistently deliver value. When done correctly, this practice helps us identify areas of waste in order to improve the process. This minimisation of waste is crucial for being Lean!

Creating Flow

Creating a consistent workflow ensures that there’s no waiting around or wasting time, thus maximising efficiency and productivity. For example, work-in-progress tasks should be limited to one at a time in order to avoid task switching and distraction, which leads to wasted time.

Establishing Pull

The idea of “Pull” is simple: start new work only when there is a demand for it and when your team has the capacity to accomplish it. Your goal should always be to produce value that is specifically needed by your customers and to avoid overproduction. The idea is to pull tasks one at a time and not all at once. The latter causes task switching and distractions, ultimately decreasing your efficiency.

Pull starts with the client in the beginning, as they are the ones that set that initial demand as the owners of the product we’re optimising. The transparency here helps us identify the right thing to do at the right time, continuously pulling through the concepts of the optimisation strategy. The effect of this practice is continuous delivery.

Pursuing Perfection

Kaizen, the concept of continuous improvement, encapsulates our goal to constantly enhance our processes by focusing on activities that generate the most value for our client while removing non-value adding activities. You can achieve this through automation, content recycling, and templating. Discipline and collaboration are also key.

However, Kaizen should be done in small increments rather than waiting too long and letting perfection get in the way of “good.”

LeanConvert and Lean Methodology

LeanConvert is one of the few optimisation companies in the world that uses Lean Methodology to deliver CRO projects. One of the key decisions we’ve made that enables us to pursue value relentlessly is moving away from hourly charging models. We work with a credit system, which shifts the attention from time spent to investment, naturally supporting more ROI.

Moreover, in order to eliminate waste from work being handed over from one team to another, we use cross-functional teams (or pods) here at LeanConvert. Each team consists of an Optimisation Consultant, a Technical Consultant, and a UX Designer. By having these people involved throughout the process, we’re able to eliminate lost information during handovers, miscommunication and misaligned priorities —thus saving us loads of time!

Why is Iterative Testing Crucial for Being Lean?

It’s safe to say we’re going to have a lot of assumptions about a website and that not all of them are going to be right. The problem is that we don’t actually know what will work or not until we try it. That’s where the test and learn approach comes in.

Companies that manage to both test and fail (yes, even fail) fast will win because they’re outlearning their competition, who in relative terms, are moving too slowly and attempting to be perfect. The secret of a 10x ROI from optimisation is a combination of focusing on the exact impact you want to achieve, mapping the impact across the specific audience base, and having a high-velocity testing program. Winning big means testing big, pivoting quickly based on results and the data available, and pursuing that value relentlessly.

Companies that spend too long trying to make a CX great before even gathering insights as to how their audience might react could be massively wasting time. Multiple smaller iterations, on the other hand, will guarantee higher velocity and more learnings than one larger iteration every couple of months.

Increasing the number of iterations also helps break down the product into smaller pieces. By running multiple tests in different areas, we have a better chance of knowing the exact effect each test has on an audience. If we only test one big change that could affect multiple areas of the product or page, we can’t know exactly what impacted the end results.

This all has to do with Boyd’s Law, which states that if you execute on changes faster and more frequently than your competitors, you’re more likely to win. The speed at which you iterate is more important than the quality of the iteration.

What’s the Connection Between Lean and Optimisation?

At their core, both Lean and optimisation share the idea that every change is a hypothesis to be tested. Both also accept that we are not perfect, but that continuous improvement will bring us as close to perfection as possible. Continuous improvement for Lean means minimising wasteful activities and increasing efficiency in the process. For optimisation, the improvement lies in iterative testing, as well as trial and error. The two go hand-in-hand (and are debatably synonymous) because of their iterative approach towards improvement.

What tools do we use for Lean Optimisation?

With value being at the core of Lean Methodology, we’re painfully aware that it is crucial to create transparency around what we’re trying to achieve and how we systematically plan to achieve it. To help us visualise, clearly identify, and weigh opportunity, we are using a series of practices that—when done consistently—never fail to let us down. The tools described below are two out of many you can use within the Lean Methodology toolbox.

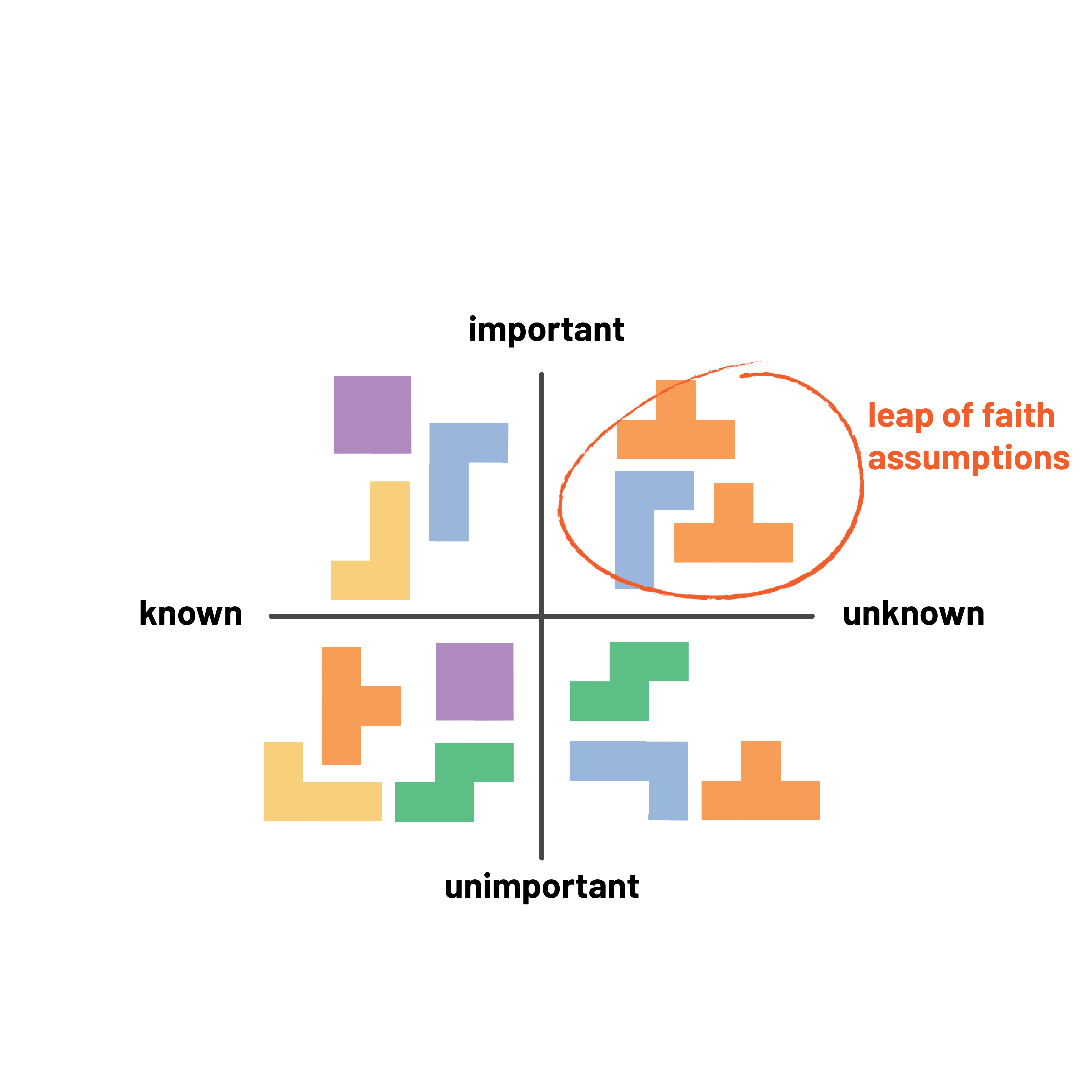

Assumption Mapping

Assumption mapping is the practice of identifying the risky assumptions we make about products. The map helps the team focus on designing experiments that matter and deliver value. While testing can be a powerful tool, you’ll need to focus your teams’ experimentation efforts on what we consider to be “important” areas, or things that can drive the most value. Otherwise, you’ll miss your window of opportunity and end up wasting time.

For example, let’s say you believe that your client’s site visitors are not completing registrations because they have too many form fields. If you don’t have any evidence yet that this is true, you place the assumption in the unknown (right) side of the map. More specifically, you please it in the “unknown and import” quadrant, because this would have a major impact on value if proven to be true. Assumptions in this quadrant should be chosen for data gathering, testing and optimisation efforts.

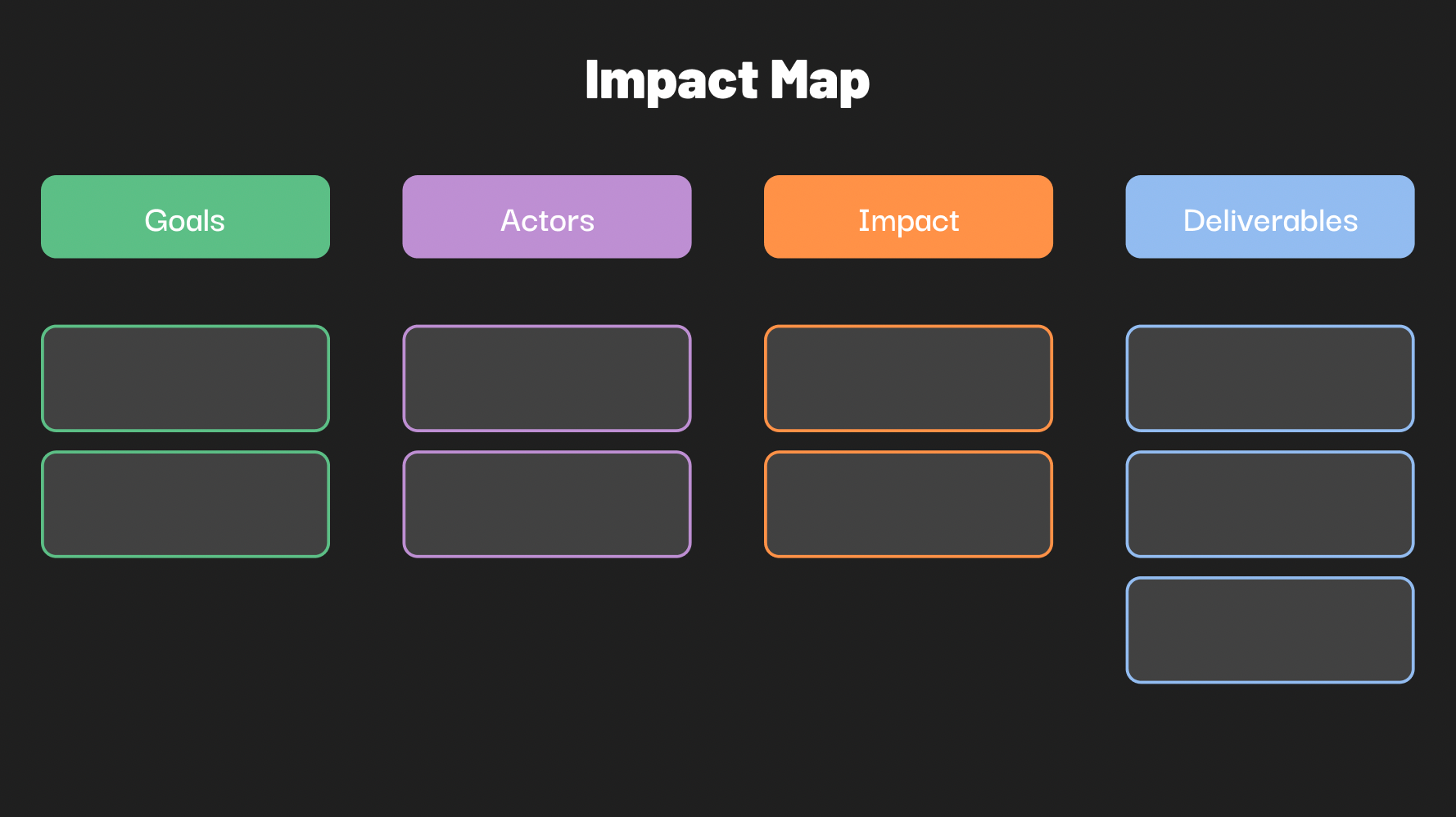

Impact Mapping

An impact map is a visual representation of your goals and the steps you must take to reach them. The point is to help decide whether a new feature or experiment actually aligns with what you’ve already established as a long-term goal. This helps the team (and the client) stay focused; if the feature or experiment does not help you reach that main goal, why would it be worth investing your time and resources?

The map has four components:

Why?

Why are you doing this? The answer to this question is the goal that the project is trying to accomplish, as measured by a specific objective.

Example: You want to increase fare upsell for an airline website by 3%.

Who?

Who can bring the organisation closer to an objective, or even, who could prevent us from reaching this objective? These people are the actors that could have an impact on the test outcome.

Example: Returning visitors who previously bought the cheapest possible fare.

How?

How should our actors’ behavior change? Do you need to change the opinions amongst internal stakeholders? Are you interested in increasing the rate of returning visitors?

Example: You want returning visitors to upgrade to the next fare on “Step 1” of the booking flow.

What?

What can the organization do to support the desired impacts? The answer to this question will identify the deliverables, which would typically be software features and experiments that you run in order to achieve the desired outcome.

Example: Publish an upsell banner that highlights the main benefits of upgrading to the next highest fare.

In Conclusion

Just as Lean Methodology preaches the importance of continuous improvement, we know that it is not a process that can be perfected overnight.

Similarly, it’s not easy to master such a powerful system by reading one article. While the above certainly lays down a foundation for you—the history, key principles, tools, and so on—the best way to learn would be to get in touch with our experts directly here at LeanConvert.

For more information or the answers to any questions, please feel free to contact us here.